Advancements in DTF Printing: Exactly How It's Changing the Sector

The textile printing sector is going through a considerable transformation, driven by the cutting-edge innovations in Direct-to-Film (DTF) modern technology. With remarkable ink solutions, improved movie and glue technologies, and the integration of automation, DTF printing supplies vivid, sturdy prints on a selection of materials, fulfilling the boosting need for personalization.

Innovations in DTF Technology

Advancing rapidly, DTF (Direct-to-Film) printing innovation has undertaken considerable renovations that are changing the textile sector. Among one of the most notable innovations is the enhancement in print quality. Modern DTF printers use innovative ink formulations that lead to vivid, resilient prints with high resolution and shade precision. These inks are particularly engineered for compatibility with different material kinds, making certain consistent quality despite the product.

Additionally, advancements in movie and sticky innovations have boosted the overall application process. New films provide far better flexibility and adhesion, improving the sturdiness and washability of the printed styles - screen printing. This guarantees that the prints keep their stability and vibrancy also after several cleans

Finally, ecological factors to consider have motivated the advancement of green DTF remedies. Manufacturers are significantly taking on sustainable methods, such as utilizing recyclable films and water-based inks, lining up with worldwide efforts to minimize the industry's ecological footprint.

Advantages Over Conventional Techniques

When contrasting DTF printing to standard techniques such as screen printing and direct-to-garment (DTG) printing, several unique advantages emerge. heat transfer vinyl printing. One of the most substantial benefits is its flexibility in fabric compatibility. Unlike display printing, which typically requires particular material types, DTF printing can be put on a more comprehensive variety of materials, including cotton, polyester, and blends, without compromising print top quality

Another remarkable benefit is cost-effectiveness, particularly for tiny to medium-sized orders. Traditional display printing becomes financially sensible only at higher volumes because of the setup costs involved. In comparison, DTF printing gets rid of these configuration expenses, making it extra budget-friendly for smaller batches and one-off layouts.

Furthermore, DTF printing excels in resilience and washability. The prints generated are robust and preserve their honesty with several wash cycles, surpassing DTG prints that might crack or fade in time. Additionally, DTF printing offers faster turnaround times. Without the demand for substantial configuration, layouts can be printed and transferred in a fraction of the time needed for screen printing.

Boosted Layout Capacities

DTF printing uses improved style capabilities that establish it apart from conventional printing techniques. The procedure entails publishing a layout onto an unique film, which is after that transferred to textile.

Additionally, DTF printing sustains a large array of fabrics, consisting of cotton, polyester, blends, and even non-textile substrates. This adaptability opens doors for creative applications in diverse industries such as fashion, home decor, and advertising items. Unlike display printing, which can be restricting because of look at more info color splitting up and pattern development, DTF printing simplifies the procedure, making multi-color and photo-realistic designs extra available.

Additionally, DTF printing succeeds in accomplishing regular color precision and vibrancy. In significance, DTF printing equips developers to push the boundaries of creativity, providing aesthetically stunning outcomes that were previously unattainable.

Price and Time Effectiveness

Among the significant advantages of DTF printing depends on its price and time performance, making it a preferred choice for numerous services. By getting rid of the requirement for screen setups and substantial pre-production processes, DTF printing considerably decreases preliminary expenses. Unlike typical techniques that need considerable financial investment in displays and configuration times, DTF printing enables for direct application onto different materials with minimal prep work. This reduction in configuration time equates right into faster manufacturing cycles, allowing companies to meet orders much more promptly.

In addition, DTF printing succeeds in producing brief runs and custom-made orders cost-effectively. The ability to create high-quality prints without the requirement for big quantity dedications lessens waste and maximizes resource allowance. This adaptability is particularly helpful for local business and startups that might not have the resources to buy large manufacturing runs.

In regards to operational efficiency, DTF printing's structured process enhances total performance. The modern technology's compatibility with a vast array of substrates and check out this site fabrics additionally widens its application see this website extent, minimizing the need for numerous printing systems. Consequently, services can achieve a much faster turn-around time, enhancing consumer fulfillment and competitiveness in the marketplace. Therefore, DTF printing sticks out as a transformative service in the printing sector.

Future Trends in DTF Printing

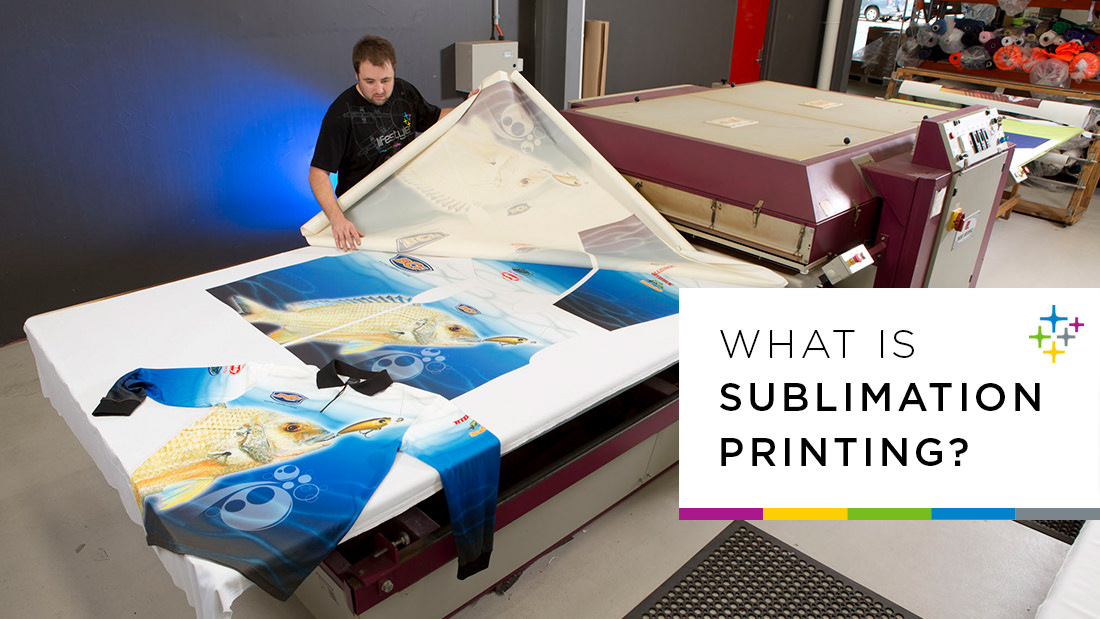

Preparing for future patterns in DTF printing reveals a landscape marked by quick technological innovations and increased market need (sublimation printing). One substantial fad is the combination of synthetic knowledge (AI) and maker knowing formulas to optimize print top quality and simplify procedures. AI-driven systems can anticipate potential problems and adjust settings in real-time, making sure continually premium outcome

In addition, improvements in sustainable materials and environment-friendly inks are anticipated to acquire grip. As ecological problems come to be a lot more important, the industry is most likely to see a change in the direction of biodegradable and non-toxic inks, decreasing its eco-friendly footprint.

Modification and customization will certainly likewise play an essential duty. With the growing customer demand for special, individualized products, DTF printing technologies are developing to supply even more detailed and comprehensive modification options. This pattern is supported by improved software program remedies that enable more complex and imaginative styles.

Lastly, the combination of DTF printing with various other electronic platforms and e-commerce services will come to be much more smooth. This connectivity will certainly make it possible for organizations to provide on-demand printing solutions straight to consumers, even more driving growth in the sector. These trends collectively highlight a future where DTF printing not just fulfills yet exceeds the progressing needs of the market.

Verdict

When contrasting DTF printing to conventional approaches such as display printing and direct-to-garment (DTG) printing, a number of unique benefits arise. Unlike screen printing, which frequently calls for particular material kinds, DTF printing can be used to a more comprehensive variety of products, including cotton, polyester, and blends, without jeopardizing print top quality.

DTF printing offers enhanced style capabilities that set it apart from conventional printing methods. Hence, DTF printing stands out as a transformative service in the printing industry.

Advancements in DTF printing considerably improve the fabric printing market by offering premium print efficiency, versatility, and high quality.